Bestseller

HeXiang Beads

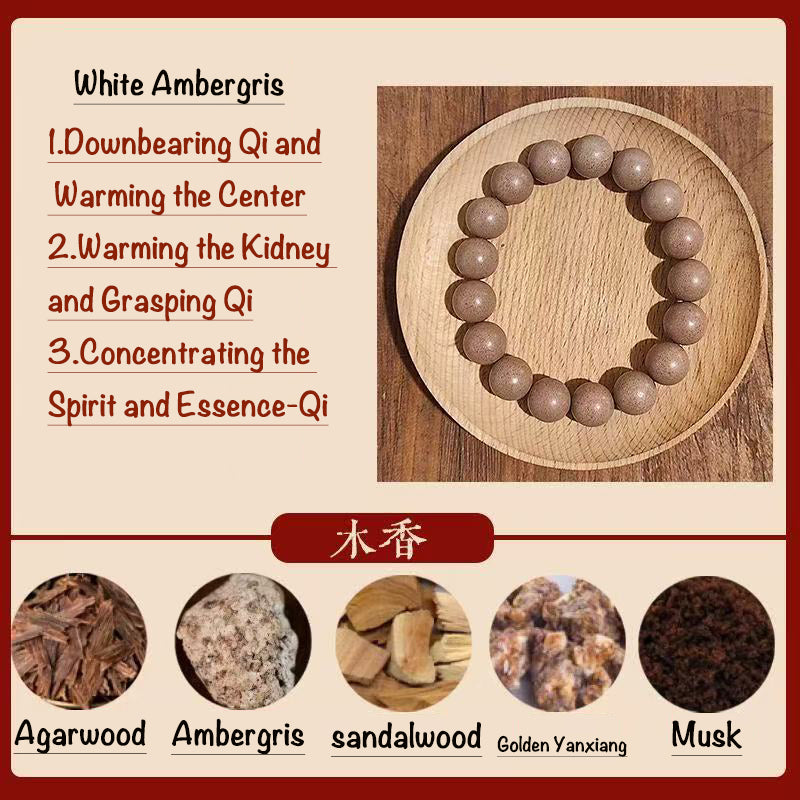

In the Qing Dynasty painting Portrait of Beauties for Yinzhen housed in the Palace Museum, a court lady holding a fan gently lowered her fair wrist, adorned with several lustrous, rounded bead strands glowing with a warm radiance. These were Hexiang beads , a fragrance accessory immensely popular in Ming and Qing imperial courts.

Crafted with herbs as their foundation and spices as their soul, these beads embodied not only the unique olfactory aesthetics of traditional Chinese culture but also encapsulated millennia of Chinese medical wisdom and literati elegance. Within their confined space, they epitomized the quintessence of Eastern lifestyle philosophy.

He Xiang Zhu (Traditional Chinese Incense Beads) Production Process

1. Material Selection

Material selection initiates the incense bead crafting process. Principal and auxiliary ingredients are chosen according to the incense formula and desired quality grade, then washed and prepared.

2. Processing Techniques

Raw materials undergo specialized processing methods – crushing, steaming, tailored to their properties. These techniques precondition the materials’ characteristics and may require repeated applications to achieve optimal states.

3. Formula Blending

All materials are ground into powder exceeding 120-mesh fineness. Following ancient "Monarch-Minister-Assistant-Courier" principles, ingredients are then systematically blended according to the incense formula.

4. Kneading & Tempering

This critical three-stage process demands half-day effort per cycle:

- Stage 1: Hand-knead incense clay on a board until resistance increases

- Stage 2: Pound with wooden hammer until compacted

- Stage 3: Forge with iron hammer until uniformly dense

Each tempering session concludes with 24-hour fermentation. Repeating this cycle 3-4 times ensures cohesive texture and develops mellow, harmonious fragrance. The matured clay is then ready for molding.

5. Polishing & Stringing

Beads undergo precision polishing before final assembly with complementary ornaments.

Frequently asked questions

He Xiang Zhu Maintenance Protocol

1. Water Exposure Prohibition

Avoid immersion in water and remove before bathing/showering to prevent material degradation.

2. Storage for Aroma Revival

When not worn long-term, store in an incense-curing box to rejuvenate fragrance potency.

3. Initial Handling Procedure

Weeks 1-2: Use gloves during polishing sessions to establish protective patina.

Post-week 2: Transition to bare-handed polishing with clean hands.

4. Chemical Contamination Prevention

Shield from perfumes, cosmetics, and detergents to preserve aromatic integrity.

5. Humidity Control & Mold Remediation

Storage: Maintain in cool, dry environments.

Mold Treatment: Gently brush affected areas with soft-bristle brush if dampness occurs; remains wearable after treatment.

6. Surface Irregularity Correction

Color variations from uneven patina or water contact normalize through routine polishing.

Origin of He Xiang Zhu: Fusion of Daoist Alchemy and Incense Culture

The genesis of He Xiang Zhu dates to the Spring and Autumn Period (770-476 BCE), when aromatic materials primarily served religious rituals and court ceremonies. Its earliest documented record appears in the Tang Dynasty Daoist canon Sandong Zhunang (三洞珠囊, "Three Caverns Pearl Pouch"), which prescribes: "Grind assorted fragrances into pellets the size of wutong seeds, strung upon green silk threads" – marking its emergence as an auxiliary tool for Daoist neidan (internal alchemy) cultivation.

Daoist practitioners harnessed aromatic resonance to:

- Harmonize the zang-fu organs (五脏)

- Unblock meridians and open orifices (通络开窍)

Integrating cauldron refinement (丹鼎) principles, they established a health preservation system based on the concept of "shared origins of fragrance and medicine" (香药同源).

Archaeological evidence confirms this early incense culture, with Han Dynasty tombs (e.g., Mawangdui, 2nd c. BCE) yielding preserved fragrant botanicals like magnolia buds (辛夷) and eupatorium (佩兰).

Customization process

1.Standard Customization: Production initiates within 48 hours after order placement.

2.Complex Craftsmanship: Recreating ancient prescriptions requires 15-day shade-drying, with total lead time approximately 30-35 days.

3.Expedited Service: Generally unavailable from most suppliers.

How much does shipping cost?

Shipping is calculated based on your location and the items in your order. You will always know the shipping price before you purchase.